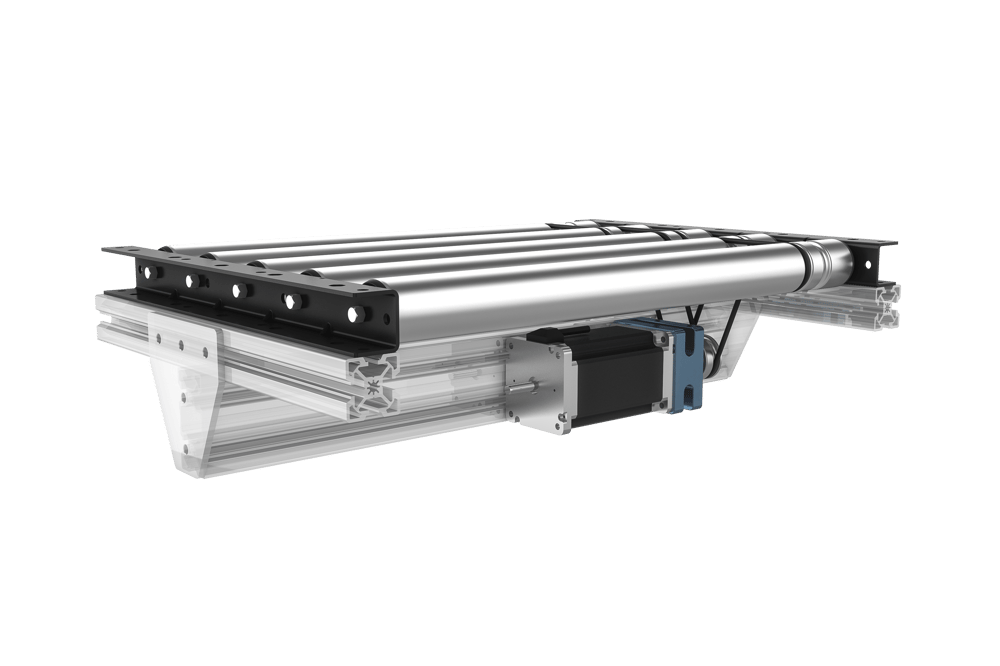

Movement minimization for unit distances in conveyor flow shop processing. 60 mm 4 Inner Roller dia.

Drawing Of Conveyor Rollers Cinta Transportadora Rodillo

International Research Journal of Engineering and Technology IRJET e-ISSN.

. In a powered roller conveyor all or a selected number of rollers are driven by one or a number of motors depending on the selected drive arrangement. In a powered roller conveyor all or a selected number of rollers are driven by one or a number of motors depending on the selected drive arrangement. ROLLER BANK TURN An assembly of segment rollers in a horizontal framed arc conforming to the degree of turn required for the track of an overhead conveyor.

POLY V PHOTO EYE PHOTO EYE REFLECTOR REFLECTOR POWERED ROLLER Each zone of the Powered Roller Conveyors are driven by a 24 VDC powered roller. Belt conveyors convey material with the help of belt The belt of the conveyor may be of textile strip steel woven mesh steel wire. Call or chat with our experts today for a free quote.

Gravity conveyors are design without considering the torsional effect on the roller shell. In a powered roller conveyor all or a selected number of rollers are. The powered roller conveyors may be installed at a slightly inclined position up to 10 up or up to 17 down.

Live Roller Conveyor systems. The driven rollers transmit motion to the loads by friction. New Used and Reconditioned Waste Handling and Recycling Equipment.

S ENT POWER ROLLER CONVEYOR 1 Length of one roller conveyor. 2250 mm 2 Width of roller conveyor. ANSYS APDL codes or Catia V5R19 for.

Dimension capacity and speed B. Pdf Gravity Roller Conveyor Design Project design of a belt conveyor installation. Conveyors and the Holy Grail Even today a roller conveyor section follows the same basic design of utilizing a large multi-phase electric motor that attaches to a gearbox which in turn rotates a shaft that turns a sprocket that moves a chain or pulley belt combination that makes contact with all of the rollers.

The motor is contained inside a 19 roller which turns the roller. Due to failure of roller assembly in powered roller conveyors. They usually consist of frames that support rollers wheels or belts and may be motor powered or manual devices.

Conveyors are mechanical devices or assemblies used to move items or packages with minimal effort. The Powered roller conveyor design is robust and potential danger areas are covered. Total length L20 m inclination angle β3 unit capacity Z180 unith dimensions of.

Ad Designed for the Most Demanding Conveying Objectives. Study existing roller conveyor system and its design. Pneumatic conveyor systems 4.

A chain driven live roller conveyor is a conveyor where the product rides directly on the carrying rollers. Roller conveyor a optimized design can be selected on the ROLLER. Modular design improves layouteasy to reconfigure Run on demandless noise wear and energy.

Type of drive unit H. As the application changes the design of the roller may vary in terms of shaft hub and shell assembly. Ad made to your specifications.

6 Espelage W Wanke E. These carrying rollers have sprockets welded to them which in turn are powered by a chain. Gravity Conveyor systems 2.

2250 mm 2 Width of roller conveyor. Vibrating conveyor systems 5. OBJECTIVE OF THE STUDY 1 Study existing Power roller conveyor system and its Design.

Such conveyors are termed gravity roller conveyor. It designed on the basis of load carring capacity distance to be moved velocity etc. For the great majority of applications Renold conveyor chain in its many variations when fitted with suitable attachments provides a highly efficient propulsion andor carrying medium having many advantages over other types.

The rollers in each zone of the PRA and PRAC conveyors are connected. Other dimensions are available on request. CATIA Design of Belt Conveyor Belt Dimension.

Roller chain has been employed as an efficient means of transmitting power since it was invented by Hans Renold in 1880. POWERED ROLLER DRIVE BANDS. The design of a roller conveyor begins with calculation of conveyor elements for given initial data.

Assembly of segment rollers in a straight horizontal frame acting as a backup to the power chain as it is driven by the caterpillar chain dogs. The advantages of the Motorized Roller Conveyor are. Power-Pack Conveyor Company 38363 Airport Parkway Willoughby OH 44094 Phone.

This manual will explain the various types of Mathews chain driven live roller conveyors manufactured by. 55 Conveyor roller The delivery time for standard conveyor rollers is approximately 1 week. General information Safe and robust construction.

Ad New Used and Reconditioned Waste Conveying and Recycling Equipment. The design of a belt conveyor system takes into account the followings. The features of PAR conveyor is the fully accumulating drive take-up and intermediate sections or midsections.

Check design of existing conveyor system. Modeling of powered roller conveyors. Design roller conveyor to reduce weight.

Components of powered roller conveyors are shaftAxle rollers frame chain selection of bearing etc. 666 mm 3 Outer Roller dia. PAR conveyor allows loads to be added to a conveyor line without disruption or movement of loads already present.

Systecs powered roller conveyor is provided as powered accumulating roller PAR or powered roller only PRO conveyor. Standard dimensions for box sizes are 300mm x 400mm and 400mm x 600mm are available. Roller diameter CBelt power and tension DIdler spacing E.

Generally these conveyors operate at horizontal plane but at times a gentle slope is given to these conveyors to aid motion of the loads. -Vertical conveyor systems and spiral conveyors 7. Driven live roller conveyor you require.

Rollers pneumatic cylinder etc. OBJECTIVE OF THE STUDY The following are the objectives of the study. So design analysis of the roller assembly that should with stand up to the total weight more than 2000Kg without failure in running conditions is the desired goal.

7 Sekimoto C. Belt Conveyor Figure 2. Individual lengths and widths.

08 mm 6 6. In this project the present powered Fig. Control mode Figure 1.

An inclination of 15 to 3 ensures that the load will roll by gravity. In most of the research papers crucial parts of roller conveyors like Roller chassis and columns and bearings were targeted for weight optimization. 44 mm 5 Roller thickness.

Analysis of Powered Roller Conveyor Shital bhosale1 AVGaur2 1 MEStudent Mechanical-Design Engineering Brahmdevdada Mane Institute of Technology Solapur. 20 Scope of Present Study. Motorized Roller Conveyors Industrial Conveyor Specialists Phone.

Powered Belt Conveyor 2systems 3. Flexible conveyor systems 6. Lower power consumption Low voltagesafety and lower cost.

SPECIFICATION OF CURRENT POWER ROLLER CONVEYOR 1 Length of one roller conveyor. Request Your Custom Designed Solution Today.

Design And Weight Optimization Of Gravity Semantic Scholar

Roller Conveyor Datasheet Vention

Belt Conveyors Principle Conveyor Engineering Tools Conveyors

Pdf Gravity Roller Conveyor Design Architecture Sketch Conveyor Design

Portable Belt Conveyor Conveyor Conveyors Mechanical Engineering Design

Design And Analysis Of A Roller Conveyor System For Weight Optimization And Material Saving Semantic Scholar

From Our Standard Range Of Aluminium Belt Conveyors To Heavy Duty Belt Conveyors Trough Belt Conveyors Bucket Elevator Conveyors Conveyor Mechanical Design

0 comments

Post a Comment